Your cart is currently empty!

Parker Autoclave’s products are designed to be safe and reliable while operating under extreme pressure and temperature conditions. With pressures, up to 150,000 psi (10345 bar), Parker Autoclave Engineers are the first choice for the petrochemical, chemical, water blast, water jet, and oil and gas industries.

Parker Autoclave Engineers provide highly engineered flow control components and systems from basic compression tube fittings to medium and high pressure cone & thread fittings, pipe fittings, needle valves, ball valves, modular fittings, and pump & valve system packages. These are designed to increase customer’s uptime, maintain safety, while improving production and quality control.

-

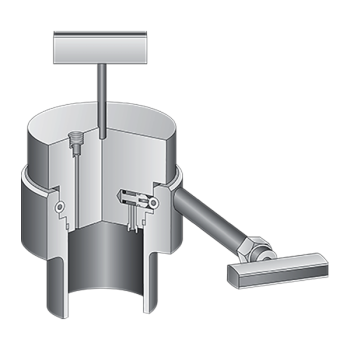

Autoclave Mini-Reactor Systems

Learn More -

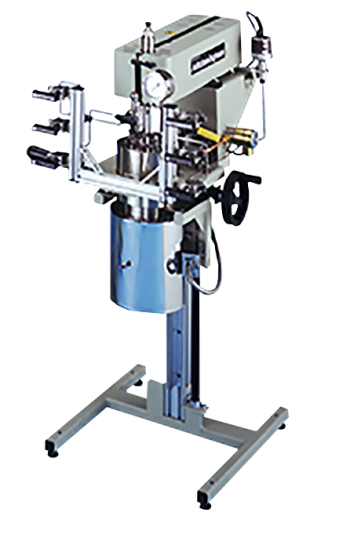

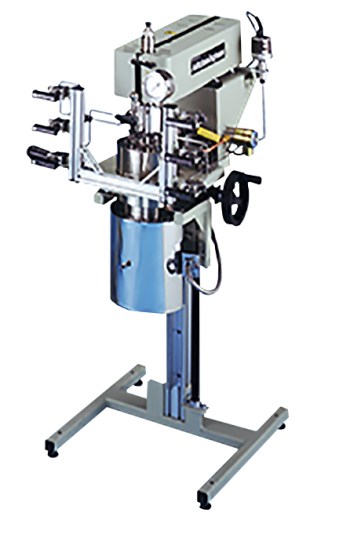

Autoclave ZipperClave® Stirred Reactor Systems

Learn More -

Autoclave Bolted Closure Reactor Systems

Learn More -

Autoclave EZE-Seal® Stirred Reactor Systems

Learn More -

Parker URC II Universal Reactor Controller

Learn More -

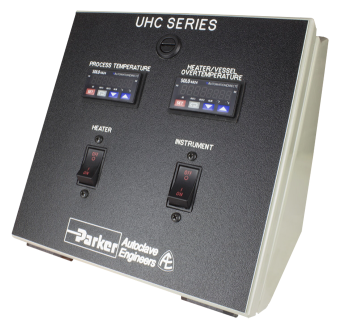

Parker Reactor Universal Heater Controller

Learn More -

Autoclave EZE-Seal Reactors

Learn More -

Autoclave Bolted Closure Reactors

Learn More -

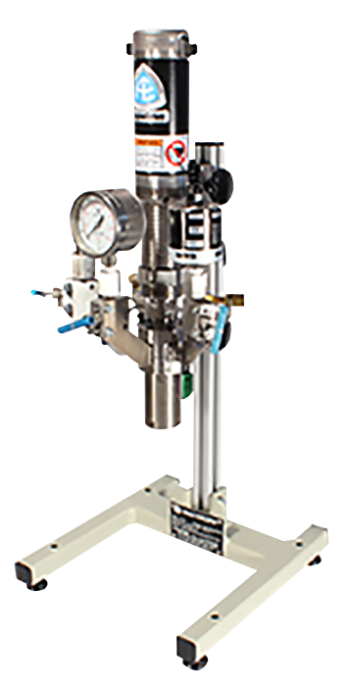

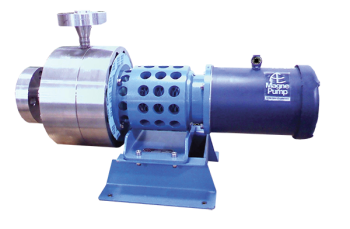

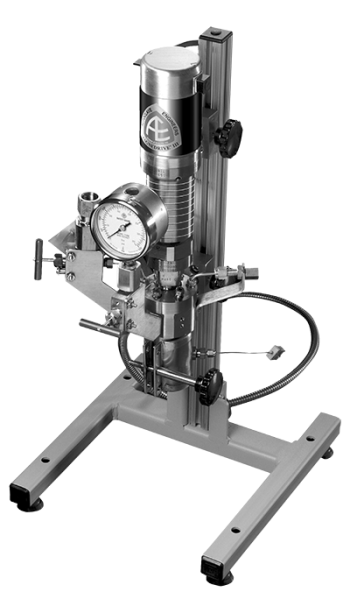

Parker Autoclave MagnePump

Learn More -

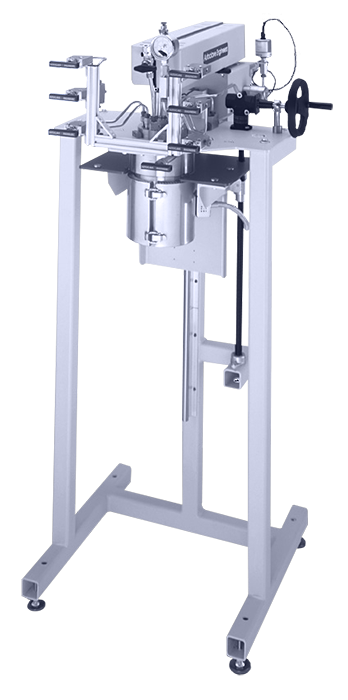

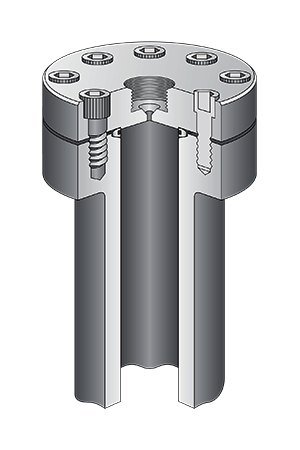

Autocalve MagneDrive Agitator MAG3050

Learn More -

Autocalve MagneDrive Agitator MAG 2.75

Learn More -

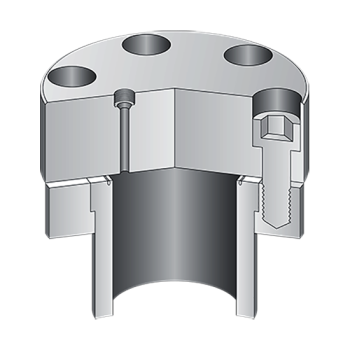

Autoclave MagneDrive Agitator MAG075

Learn More -

Autoclave Zipperclave Reactor

Learn More -

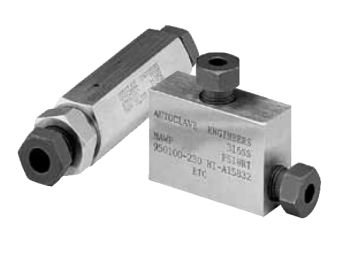

P Series Pipe Fittings

Learn More -

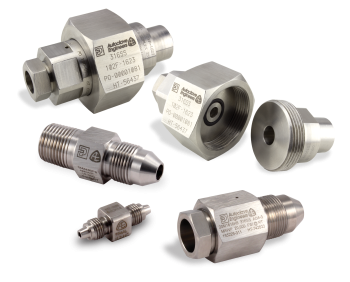

QS Series Fittings & Tubing

Learn More -

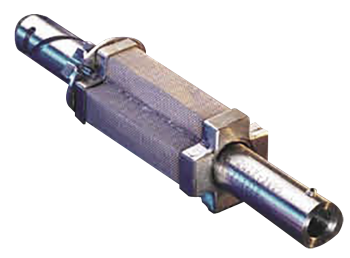

Medium Pressure Fittings & Tubing

Learn More -

Low Pressure Fittings & Tubing

Learn More -

High Pressure Fittings & Tubing

Learn More -

Adapters & Couplings

Learn More -

MicroClave™ Packless Reactor

Learn More -

Catalytic Reactor Selection Guide

Learn More