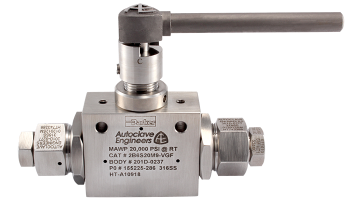

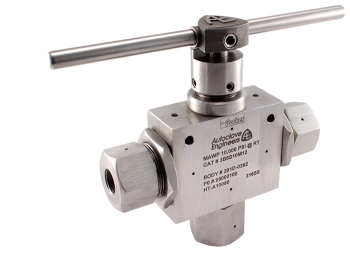

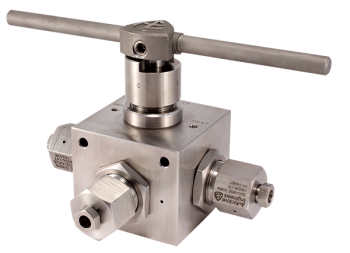

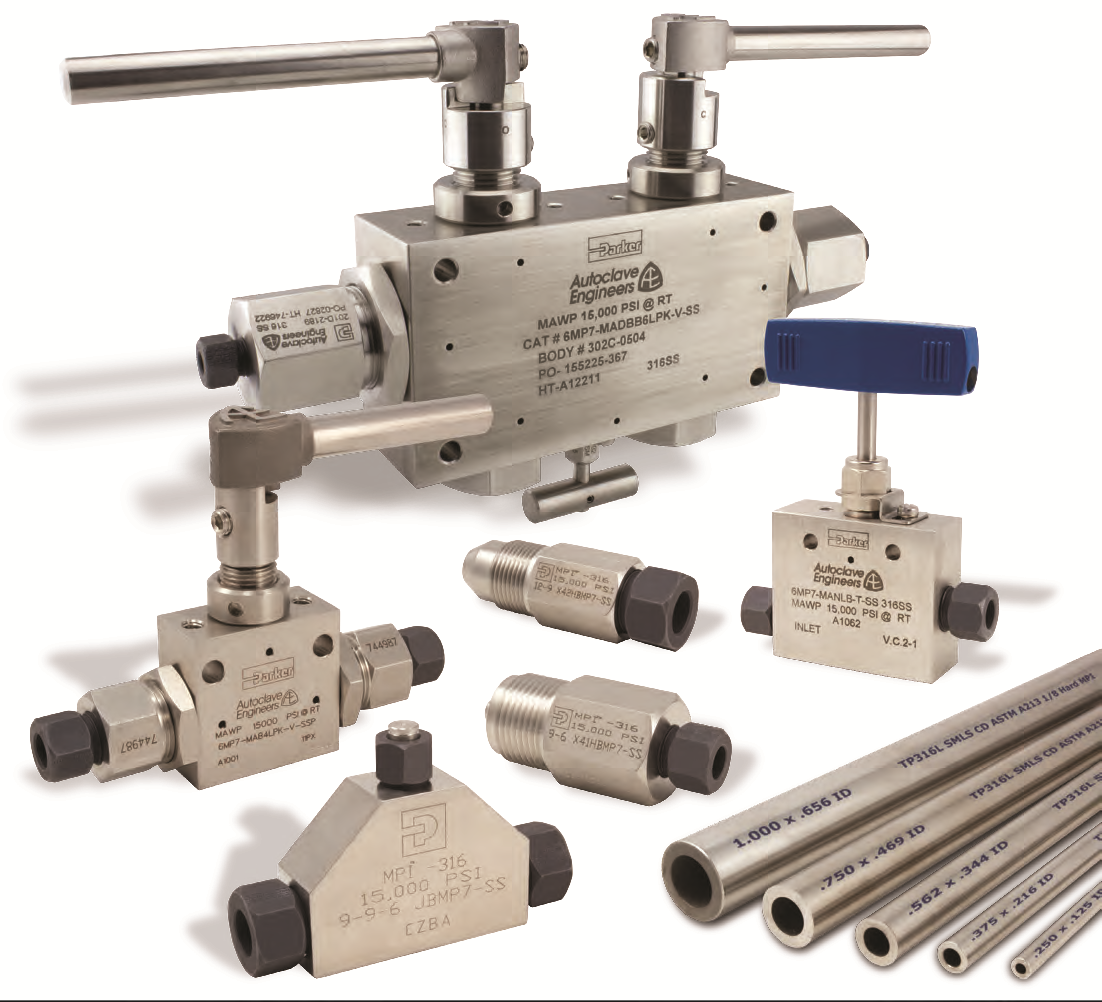

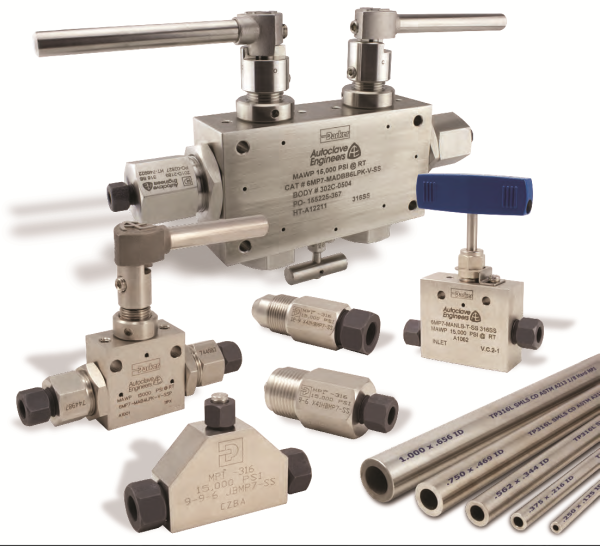

Parker Hannifin MPI™ connections are engineered and manufactured to be secure and gas-tight while being made manually (wrench turns) or hydraulically using a set tool. This connection has application throughout industry, including offshore oil and gas exploration platforms, research labs, and other facilities that require operating pressures to 15,000 psi. MPI™ Fittings are ideally suited to handle liquids, gases, or chemicals and can be used on a wide variety of tubing materials including Instrument Grade thick-walled annealed 316 SS, 1/8th Hard (cold drawn) 316 SS MPI tubing, and 2507 Super Duplex MPI tubing. Every Parker MPI™ Fitting is supplied complete with both ferrules and compression gland nut, ready to install.

Features & Benefits:

- Front ferrule with corrosion-resistant Parker Suparcase® forms a seal between the tube, body and ferrule. It also provides a mechanical hold on the tube.

- Back ferrule with corrosion-resistant Parker Suparcase® provides a strong mechanical hold on the tube.

- Longer thread area for improved resistance to pressure and load on the ferrules.

- Molybdenum disulfide-coated inverted nut helps prevent galling, provides easier assembly and permits multiple remakes.

- Long tube-support area improves resistance to vibration and the line loads.

MPI™ Fittings Pressure Ratings

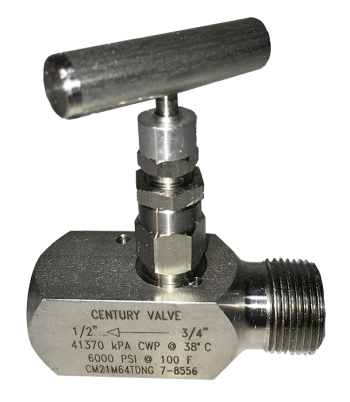

The maximum pressure rating is marked on each fitting. MPI™ working pressures to be determined by selected tubing.

- Size 4 (1/4″) MPI™ – to 15,000 psi

- Size 6 (3.8″) MPI™ – to 15,000 psi

- Size 8 (1/2″) MPI™ – to 15,000 psi

- Size 9 (9/16″) MPI™ – to 15,000 psi

- Size 12 (3/4″) MPI™ – to 15,000 psi

- Size 16 (1″) MPI™ – to 12,500 psi using 316 SS MPI tubing, 15,000 psi using MPI 2507 Super Duplex tubing with -XF Ferrule Option

Note: Tube and pipe thread sizes are designated by the number of sixteenths of an inch (1/4” tube = 4/16” or 4).