Barksdale components can be found in steel mills, auto plants, power generation and distribution facilities, chemical processing plants, pulp and paper mills, textile mills, amusement parks, food processing plants, offshore drilling rigs, oil and natural gas fields, rescue equipment, and on many forms of transportation equipment, both on and off-road.

Barksdale supplies specially designed or adapted products to meet specific conditions. Should requirements go beyond the available modification options, Barksdale’s engineers are ready to assist, even if the application requires new technologies.

Hydraulic Control + Relief Valves

Features: Heavy Duty Valves

Heavy Duty Line – directional control for fluids and gasses up to 6,000 psi

Shear-Seal® Manual Control Valve

Applications

Land-based and offshore drilling equipment

Steel mills

Nitrogen charging panels

Refineries and chemical processing plants

Power generation facilities

Working Pressure: Air (pneumatic) up to 4,000 psi (276 bar)

hydraulic oil or lubricated water up to 6,000 psi (413 bar)

Flow Capacity, Cv: See table

Back Pressure: Must not exceed 250 psi (17.2 bar) at return port for satisfactory operation

Pressure Drop: 14 psi (0.96 bar) at 20 ft/sec

See Supplemental Guide for more detailed information

Proof Pressure: 1-1/2 times working pressure except at return port

Burst Pressure: 2-1/2 times working pressure except at return port (3,000 psi [206 bar])

Features: High Pressure OEM Valves

High Pressure OEM Valve line up to 3000 psi

Shear-Seal® Manual Control Valve

Applications

Hydraulic presses

Military equipment

Paper mill controls

Hydraulic pilot valves

Railroad maintenance equipment

Halon fill systems

Working Pressure: Hydraulic fluid up to 3000 psi (206 bar)

Back Pressure: Must not exceed 250 psi (17.2 Bar) at return port for satisfactory operation

Pressure Drop: 14 psi (0.96 bar) at 20 ft/sec

See Supplemental Guide for more detailed information

Proof Pressure: 1-1/2 times working pressure except at return port

Burst Pressure: 2-1/2 times working pressure except at return port (3000 psi [206 bar])

Features: High Pressure Valve

Shear-Seal® high pressure directional control valve for fluids and gasses up to 15,000 psi

Applications

Offshore drilling equipment

Refineries and chemical processing plants

Gas compression systems

Marine umbilical reels

Working Pressure: Standard to 10,000 psi (690 bar)

Optional to 15,000 psi (1,034 bar) (on 1/4” model only)

Flow Capacity, Cv: See table

Back Pressure: Must not exceed 250 psi (17.2 bar) at return port for satisfactory operation

Pressure Drop: 14 psi (0.96 bar) at 20 ft/s

Proof Pressure: 1-1/2 times working pressure except at return port

Burst Pressure: 2-1/2 times working pressure except at return port (3,000 psi [206 bar]) maximum

Features: Subplate Mounted Heavy Duty Valve

Sub-plate mounted manifold valve – Shear-Seal® directional control for fluids and gasses up to 4,500 psi

Applications

Steel mills

Shipboard hydraulic control systems

Refineries and chemical processing plants

Power generation facilities

Working Pressure: Hydraulic oil or lubricated water up to 4,500 psi (310 bar)

Flow Capacity, Cv: See table

Back Pressure: Must not exceed 250 psi (17.2 Bar) at return port for satisfactory

operation

Pressure Drop: 14 psi (0.96 bar) at 20 ft/sec

* See Supplemental Guide for more detailed information

Proof Pressure: 1-1/2 times working pressure except at return port

Burst Pressure: 2-1/2 times working pressure except at return port (3,000 psi [206 bar])

Media Temperature

Range:

-40° to +250°F (-40° to +121°C)

Features: Barksdale’s Microtorque® valve provides superior directional control for fluid power applications up to 6,000 psi where compact design and virtually zero leakage* are a must. Utilizing Barksdale’s Shear-Seal® technology, the Microtorque® valve offers reliable performance and lapped metal-to-metal sealing surfaces that will easily tolerate contaminated fluids. This valve offers many options that make it extremely versatile including panel mounting, spring return, 2 or 3 position detents, DO3 manifold mounting, and non-interflow. Leveraging the flexibility and unique features of the Microtorque® valve, along with its superior performance, can result in bottom line savings and operational benefits for your customers.

Media: Hydraulic oil

Working Pressure: 6,000 psi (415 bar) **

Flow Capacity, Cv: See table

Back Pressure: Must not exceed 250 psi (17.2 bar)*** at return port for satisfactory operation

Proof Pressure: 1-1/2 times working pressure except at return port

Burst Pressure: 2-1/2 times working pressure except at return port

Media Temperature

Range:

-40° to +250°F (-40° to +121°C)

Porting: 1/4” NPT, SAE for 1/4” tubing, or DO3 pattern for manifold mounting

Features: The Model 8014, part of the new 8010 series, incorporates all the manufacturing knowledge and experience that has earned Barksdale a reputation for top quality and reliability in the market. This unit is a 3/4″ NPT relief valve intended for use in hydraulic systems. All stainless steel internals and a corrosion-resistant powder-coated external housing makes this product perfect for heavy industrial environments in the most demanding applications.

Working Pressure: Hydraulic oil up to 5500 psi (380 bar)

Proof Pressure: 10,000 psi (690 bar)

Pressure Ranges: 200 – 500 psi (15 – 35 bar)

500 – 1500 psi (35 – 105 bar)

1500 – 3500 psi (105 – 240 bar)

3500 – 5500 psi (240 – 380 bar)

Flow Rate: 15 GPM (NOMINAL)

Wetted Material: Fitting: Heat-treated 410 stainless steel

Internals: 416 stainless steel

Spring: Powder-coated high strength steel

Ball: Tungsten Carbide

Housing: Powder-coated ductile iron

Pressure Connection: 3/4” NPTM x 3/4” NPTF

Temperature Range: -40° to +200°F (-40° to +93°C)

Features: Barksdale’s Series 9000 Valves control hydraulic fluids and gasses up to 350 psi. Featuring Barksdale’s famous Shear-Seal® technology, the Series 9000 Valves offer dependable performance and long life for manual control of commercial and industrial process applications. The versatile design of this valve offers the ability to tailor the perfect configuration to meet your installation requirements.

Working Pressure: Pneumatic or hydraulic from 150

psi to 350 psi (10.3 to 24.1 bar); see table

Cv, Minimum Orifice: See table

Back Pressure: Must not exceed 250 psi (17.2 bar) at return port for satisfactory operation

Proof Pressure: 1-1/2 times working pressure except at return port (without damage to valve)

Burst Pressure: 2-1/2 times working pressure except at return port (300 psi, 20.7 bar)

Features: Barksdale’s Low Pressure OEM Valve line provides exceptional directional control for fluids and gasses up to 500 psi in the toughest industrial applications. Using Barksdale’s Shear-Seal® technology the OEM Valve products offer dependable performance and long life even when the media being controlled is contaminated with debris that would ruin ordinary valves. Flexibility is built into the Low Pressure OEM Valve line which features several standard options that can be adapted to meet the unique needs that OEM customers require in their products.

Working Pressure: Gasses or hydraulic fl uids up to 500 psi (34 bar)

Flow Capacity, Cv: See table

Back Pressure: Must not exceed 250 psi (17.2 bar) at return port for satisfactory operation

Pressure Drop: 14 psi (0.96 bar) at 20 ft/sec

See Supplemental Guide for more detailed information

Proof Pressure: 1-1/2 times working pressure except at return port

Burst Pressure: 2-1/2 times working pressure except at return port (500 psi [34 bar])

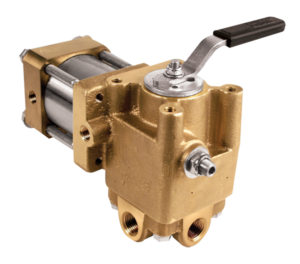

Features: Barksdale’s patented Series II valve provides an optimal solution by combining the dependable features of our heavy duty Shear-Seal® valves with the reliability of a rack and pinion pilot actuator, all in one integrated package. With the ability to handle high velocity flows at pressures up to 6000 psi and tolerate contaminated media, the Series II valve becomes the choice for the toughest applications.

Working Pressure: Hydraulic up to 3,000 or 6,000 psi (206 bar or 413 bar)

Air up to 2,000 or 4,000 psi (138 or 276 bar)

Back Pressure: Must not exceed 250 psi (17.2) bar at return port for satisfactory operation

Proof Pressure: 1-1/2 times working pressure except at return port

Burst Pressure: 2-1/2 times working pressure except at return port (3,000 psi [206 bar])

Pressure Drop

(all Valves):

Porting: 1/4”, 3/8”, 1/2”, 3/4”, 1”, & 1-1/2”

NPT Standard (SAE J1926 Option)

Media Temperature

Range:

-40° to +250°F (-40° to +121°C)

Hydraulic Regulators

Features: Barksdale’s Model 20415 is a sensitive pressure-control device used to maintain a pre-determined pressure in a hydraulic circuit. The regulated output pressure can be controlled either by the force of a spring, or a motor (hydraulic or pneumatic). Design features ensure excellent accuracy, repeatability and high flow coefficients.

Pressure:

Supply/Inlet Pressure: 5,000 psi (345 bar)

Regulated Pressure Range (manual): 300-3000 psi (21 – 207 bar)

Regulated Pressure Range (failsafe motor): 500-2400 psi (34 – 165 bar)

Fluid Temperature Range: -40° to +250°F (-40° to +121°C)

Proof Pressure: 7,500 psi (517 bar)

Burst Pressure: 12,500 psi (862 bar)

Flow:

Flow Rate: 70 GPM

Outlet Cv: 9.8

Vent Cv: 0.6

Porting:

Inlet:1” NPT

Outlet (regulated): 1” NPT

Vent: 1/2” NPT

Gauge Port: 3/8” NPT

Features: Barksdale’s Model 20313 is a sensitive pressure-control device used to maintain a pre-determined pressure in a hydraulic circuit. The regulated output pressure can be controlled either by the force of a spring, or a motor (hydraulic or pneumatic). Design features ensure excellent accuracy, repeatability and high flow coefficients.

Pressure:

Supply/Inlet Pressure: 5,000 psi (345 bar)

Regulated Pressure Range (manual):

High Sensitivity: 300 – 1600 psi (21 -110 bar)

Full Range: 300 – 3000 psi (21 – 207 bar)

Regulated Pressure Range (failsafe motor):

High Sensitivity: 300 – 1600 psi (21 -110 bar)

Full Range: 300 – 3000 psi (21 – 207 bar)

Fluid Temperature Range: -40° to +250°F (-40° to +121°C)

Proof Pressure: 7,500 psi (517 bar)

Flow:

Flow Rate: 45 GPM (@ 50/ft/s)

Outlet Cv: 6.7

Vent Cv: 6.7

Porting:

Inlet:1/2” NPT

Outlet (regulated): 1/2” NPT

Vent: 1/2” NPT

Bleed Port: 1/4” NPT

Features: Barksdale’s Model 20495 Increased Sensitivity Regulator is a modified version of the Heavy Duty regulator, designed to allow more control at low pressures. This version offers better reaction time and better set point accuracy. The regulated output pressure can be controlled either by the force of a spring, or a motor (hydraulic or pneumatic). Design features ensure excellent accuracy, repeatability and high flow coefficients.

Pressure:

Supply/Inlet Pressure: 5,000 psi (345 bar)

Working Pressure: 3,000 psi (207 bar)

Regulated Pressure Range (manual): 300-2700 psi (21 – 186 bar)

Regulated Pressure Range (failsafe motor): 400-2400 psi (28 – 165 bar)

Fluid Temperature Range: -40° to +250°F (-40° to +121°C)

Proof Pressure: 7,500 psi (517 bar)

Flow:

Flow Rate: 70 GPM

Outlet Cv: 9.8

Vent Cv: 0.6

Porting:

Inlet:1” NPT

Outlet (regulated): 1” NPT

Vent: 1/2” NPT

Gauge Port: 3/8” NPT

Features: Barksdale’s Model 20337 is a sensitive pressure-control device used to maintain a pre-determined pressure in a hydraulic circuit. The regulated output pressure can be controlled either by the force of a spring, or a motor (hydraulic or pneumatic). Design features ensure excellent accuracy, repeatability and high flow coefficients.

Pressure:

Supply/Inlet Pressure: 3,000 PSI (207 bar)

Regulated Pressure Range (manual):

Base Model: 180 – 1600 PSI (12 – 110 bar)

-1 Model: 350 – 2800 PSI (24 – 193 bar)

API Compliance: API 16D, 4.3.2.2

Fluid Temperature Range: -40° to +250°F (-40° to +121°C)

Proof Pressure: 4,500 PSI (310 bar)

Burst Pressure: 7,500 psi (517 bar)

Flow:

Flow Rate: 120 GPM (@ 50 ft/s)

Cv 1 inlet: 11.4

Cv 2 inlet: 17.5

Porting:

Inlet 1: 1” NPT

Inlet 2: 1” NPT

Outlet (regulated): 1-1/2” NPT

Vent: 1/2” NPT

Pressure Transducers

Features: Lightweight, compact and all-welded rugged stainless steel construction Thin-film & diffused silicon sensors for high accuracy

Optional HART® communication protocol with diagnostics & field calibration, reducing maintenance time and cost; and 10:1 turndown ratio for rangeability, maintaining high accuracy and allowing one part for multiple pressure ranges

Available pressure ranges up to 30,000 PSI

High accuracy down to 0.1% FSO, LHR

cULus, ATEX, IECEx and Single Seal certifications

Explosion proof enclosure with IP66 / IP67 and NEMA 4X, 7 & 9 ratings CE, CRN, NORSOK and NACE compliant and Superior EMI, ESD and RFI protection

Factory sealed, environment friendly, halogen free wires and cable

Features: Barksdale’s 440 Series Intrinsically Safe Transducers provide high accuracy pressure measurement when operating in Class I, Division I environments. Intrinsically safe transducers prevent personal injury and machinery damage by preventing the explosion in the first place. External zener barriers are required in order to meet UL requirements for an intrinsically safe installation. The higher cost of having to install a zener barrier is offset with the comfort of knowing that an explosion will not occur within normal operating conditions. Three models are available: Series 443 (0-5V), Series 445 (4-20mA) and Series 446 (0-10V).

Accuracy (LH & R): ±0.25% FSO at 75°F (±0.5% for vacuum only [-23]) typical

Long Term Stability: ±0.5% FSO of calibration curve

Typical Life Cycle: 100 million cycles

Proof Pressure: 2 times rated pressure or 13,000 psi max. (884 bar), whichever is less

Series 445

• Excitation voltage: 12 to 28 VDC

• Output: 4 to 20 mA

• Full scale output: 16 mA ± 1%

• Zero output: 4 mA ± 2%

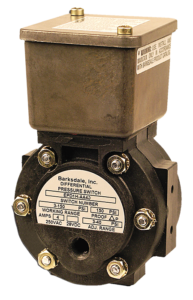

Switches - Differential

Features: Barksdale’s Housed Diaphragm Differential Pressure Switches offer superior accuracy in a robust package, making them an ideal solution to your industrial pressure control needs. These switches are ideal applications requiring water-tight, NEMA 4 housings, a covered terminal strip and tamper-proof external adjustment. (Unit can be factory set upon request.) With pressure ranges up to 150 psi, these housed diaphragm differential pressure switches are suitable for use in either positive pressure or vacuum applications. Available in single-circuit and dual-circuit models. These switches feature a durable, die-cast aluminum enclosure. For applications requiring a highly accurate switch in a durable package, Barksdale’s Housed Diaphragm Differential Pressure Switches are the ideal choice.

Electrical Characteristics: All models incorporate Underwriters Laboratories, Inc. and CSA Listed single

pole double throw snap-action switching elements

Accuracy: ± 5% of the adjustable range

Switch: SPDT snap action 4 amps @ 125/250 VAC (Class AA limit switch); 5 amps @ 125/250 VAC (Class BB limit switch).

Wetted Parts:

Polysulfone, 40% glass filled

Dacron reinforced neoprene

Polysulfone, 40% glass filled

Electrical Connection:

12” free leads or

3-contact terminal block

Features: Barksdale’s CDPD1H and CDPD2H Housed Diaphragm Differential Pressure Switches are the answer for pressure control applications requiring tamper proof external adjustment and environments which require water-tight NEMA 4 housings. These pressure switches are available in single or dual control settings for both positive pressure and vacuum models, to 150 psi. The switches may be wired normally open or normally closed through a 3/4″-14 NPT conduit connection to free leads. All models feature calibrated dials for adjusting setpoints in units can be factory set upon request. For applications requiring a highly reliable, accurate switch in a durable package, Barksdale’s CDPD1H and CDPD2H Housed Diaphragm Differential Pressure Switches are the ideal choice

Electrical Characteristics: All models incorporate Underwriters’ Laboratories, Inc. listed single pole

double throw snap-action switching elements. Switches may be wired “normally open” or “normally closed”.

Accuracy: ± 0.5% of the adjustable range

Switch: SPDT single or dual circuit 10 amps @ 125/250 VAC; 3 amps @ 480 VAC (Class A or H limit switch)

Wetted Parts: 17-7 PH stainless steel Viton®

Die-cast aluminum anodized

Nickel painted aluminum

300 series stainless steel

Electrical Connection: Free leads approximately 18” long No. 16

AWG standard AWN 105/c wire through 3/4” conduit connection.

Enclosure Ratings: Housed watertight housing (NEMA 4) Tamper-proof external adjustment.

Features: Barksdale’s Housed Diaphragm Differential Pressure Switches offer superior accuracy in a robust package, making them an ideal solution to your industrial pressure control needs. These switches are ideal applications requiring water-tight, NEMA 4 housings, a covered terminal strip and tamper-proof external adjustment. (Unit can be factory set upon request.) With pressure ranges up to 150 psi, these housed diaphragm differential pressure switches are suitable for use in either positive pressure or vacuum applications. Available in single-circuit and dual-circuit models. These switches feature a durable, die-cast aluminum enclosure. For applications requiring a highly accurate switch in a durable package, Barksdale’s Housed Diaphragm Differential Pressure Switches are the ideal choice.

Accuracy: ± 0.5% of the adjustable range

Switch: SPDT snap action; single or dual circuit 10 amps @ 125/250 VAC; 3 amps @ 480

VAC (Class A or H limit switch). Consult product configurator for ratings of optional limit switches.

Wetted Parts: 17-7 PH stainless steel Viton®

Die-cast aluminum anodized

Nickel plated aluminum

300 series stainless steel

Electrical Connection: Screw terminals on covered terminal strip through 1/2” NPT conduit fitting

Enclosure Ratings: NEMA 4

Pressure Connection: 1/8” NPT female high + low

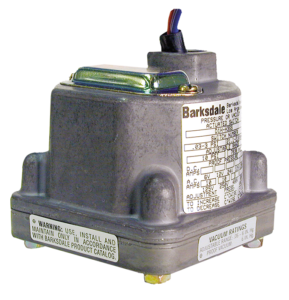

Switches - Pressure, Explosion Proof

Features: Barksdale’s explosion proof compact pressure switches are ideal for hazardous location hydraulic applications and many of your other industrial control needs. Series 9671X/9681X are available in vacuum and pressure ranges up to 500 psi with a high proof pressure of 1000 psi, and series 9692X is available in pressure ranges up to 10,000 psi with a high proof pressure of 15,000 psi, these pressure switches come with a SPDT or DPDT limit switch. The rugged design provides you with the reliability you need for your mission critical applications.

Accuracy: ±2% of full scale

Typical Life: 2.5 million cycles

Switch: SPDT, snap action, Class CC simulated DPDT (optional)

Electrical Connection: 1/2” NPT male conduit connection, 18 AWG, 18” (300 mm) free leads

Electrical Rating: 11 amps @ 125/250VAC

5 amps @ 30 VDC (CC Class)

Enclosure Ratings: NEMA 4X, 7 & 9

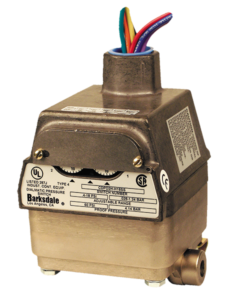

Features: Barksdale’s D1X and D2X Explosion Proof Diaphragm Pressure Switches offer high accuracy and reliability, providing an ideal solution for your hazardous locations pressure control requirements. With vacuum and positive pressure ranges to 150 psi, NEMA 4,7,& 9 enclosures, a covered terminal strip and tamper-proof external adjustment, Barksdale D1X and D2X Explosion Proof Diaphragm Pressure Switches meet your needs in a wide variety of applications. These switches are available in single setting or dual control. An internal set screw allows for easy internal adjustment of setpoints. For applications requiring a highly accurate switch in a durable package, Barksdale’s Explosion Proof Diaphragm Pressure Switches are the ideal choice.

Accuracy: ± 0.5% of the adjustable range

Single pole double throw (SPDT) Snap

Action; single circuit

10 amps @ 125/250 VAC; 3 amps @ 480 VAC (Class A or H limit switch).

Consult sales drawing for ratings of optional limit switches.

Electrical Connection: Screw terminals on covered terminal strip via 1/2” NPT (D1X) and 3/4” NPT (D2X) conduit fittings.

Enclosure Ratings: NEMA 4, 7, 9

Pressure Connection: 1/4” NPT Female

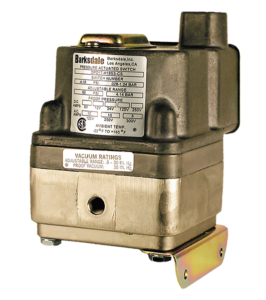

Features: Barksdale’s P1X Series Explosion Proof Pressure Switches offer extremely long life and the accuracy you need for your pressure control applications in hazardous locations. Designed with Dia-Seal Piston technology, the P1X assures millions of maintenance free, leakage free cycles. A rugged NEMA 7, & 9 enclosure makes this switch an ideal choice for indoor installations. Setpoints are easily adjus ted via a tamper-proof external adjustment screw, and the switch can be safely adjusted within the hazardous location. Designed to control pressures up to 1600 psi, the P1X Series Explosion Proof Pressure Switches are an outstanding choice for your demanding hazardous area applications.

Explosion Proof Dia-Seal Piston

Explosion proof, long life, high cycle, NEMA 7 & 9 enclosure, ranges from .5 – 1,600 psi

Features: Barksdale’s B1X and B2X Explosion Proof Bourdon Tube Pressure Switches offer instrument class accuracy, making them an ideal solution to your hazardous location pressure control needs when accuracy is critical. Built-in over-travel stops allow for higher proof pressures than most other pressure switch technologies. Setpoints are easily adjusted via an internal adjustment screw. Available in single and dual circuit configurations, Bourdon Tube Pressure Switches are adaptable for use in a wide range of industrial applications. A variety of limit switches is available to allow for a multitude of electrical switching conditions. For applications requiring a highly accurate switch in a highly durable package, Barksdale Bourdon Tube Pressure Switches are the ideal solution.

Electrical

Characteristics: All models incorporate Underwriters Laboratories, Inc. and CSA Listed single pole double throw snap-action switching elements.

Accuracy1: ± 1% of the adjustable range

Switch:

Type:

Rating:

Single pole double throw (SPDT) snap action; single or dual circuit 3 amps @ 480 VAC (standard)

Wetted Parts:

Process Fitting & Bourdon Tube:

Enclosure:

316 series stainless steel

Die-cast aluminum

Electrical Connection:

Internal terminal strip via conduit

connection (1/2” NPT on B1X models, 3/4” NPT on B2X models)

Enclosure Ratings: NEMA 4, 7, 9

Pressure Connection: Models with proof pressures up to 7,200

psi: 1/4” NPT Female; Models with higher pressure ranges: Superpressure Fitting for

1/4” O.D. tube

Switches - Pressure, General Purpose

Features: The Series 96201 Pressure Switches offer a durable and versatile solution to your pressure control problems in a compact, economical package. A wide range of factory options is available in plastic, brass or stainless steel, allowing the switch to be custom configured to the exact needs of your application. With the addition of an optional conduit connector, the switch becomes watertight and bears a NEMA 4 rating. The addition of optional DIN electrical connector allows for ease of installation and maintenance. Designed to control pressures from vacuum up to 7500 psi, the Series 96201 Pressure Switches are an outstanding choice to meet your demanding industrial applications.

Accuracy: ± 2% of full range

Switch: SPDT snap action; single circuit

5 Amp @ 125/250 VAC (Class BB microswitch – standard)

10 Amp @ 125/250 VAC (Class CC microswitch)

5 Amp @ 30 VDC (Class BB and CC microswitches)

Pressure Connection: 1/4” NPT male (standard)

Features: Barksdale’s Diaphragm Pressure Switches offer superior accuracy in a robust package, making them the ideal solution to your industrial pressure control needs. Diaphragm switches are ideal for applications demanding instrument class accuracy and where pressure pulsations are less than 25 cycles per minute. Available in various pressure ranges up to 150 psi, diaphragm switches are suitable for use in either positive pressure or vacuum applications. Single, and dual, and triple circuit models are available. Housed models (D1H & D2H) feature a durable, anodized aluminum enclosure with an integrated 1/2″ NPT conduit connector, a tamper-resistant cover for the setpoint adjustment screws, and are rated to NEMA 4 as a standard. For applications requiring a highly accurate switch in a durable package, Barksdale’s Diaphragm Pressure Switches are the ideal choice

Accuracy: ± 0.5% of the adjustable range

Switch: Single pole double throw (SPDT) Snap

Action; single or dual circuit

10 amps @ 125/250 VAC; 3 amps @ 480 VAC (Class A or H limit switch).

Consult sales drawing for ratings of optional limit switches.

Pressure Connection: 1/4” NPT Female

Features: Barksdale’s P1H Series Pressure Switches offer extremely long life and the accuracy you need for your industrial applications. Designed with Dia-Seal Piston technology, the P1H Series Pressure Switches ensure millions of maintenance free, leakage free cycles. A rugged, NEMA 4 enclosure makes these pressure switches an ideal choice for both indoor and outdoor installations. Setpoints are easily adjusted via an external adjustment screw. Designed to control pressures up to 1600 psi, the P1H Series Pressure Switches are an outstanding choice for your demanding industrial applications.

Electrical Characteristics: All models incorporate Underwriters Laboratories, Inc. and CSA Listed single pole double throw snap-action switching elements

Accuracy: ± 2% of the adjustable range

Switch: Single pole double throw (SPDT) snap action; single circuit (see order key for ratings)

Pressure Connection: 1/4” NPT female (standard)

Features: The Series 7000 Pressure Switch delivers powerful performance in a compact, economical package. Available in stainless steel or brass, this switch measures, controls and switches pressures up to 3000 psi. A snap action micro-switch eliminates the inconsistent operation of floating contacts found in similar designs. This UL Recognized and CSA listed switch can be used for high or low pressure control, safety shutdown and alarm functions for most industrial equipment applications. When the application is critical and space is limited, the Series 7000 is the switch to choose.

Electrical Characteristics: All models incorporate Underwriters’ Laboratories, Inc. and CSA Listed

single pole double throw snap-action switching elements.

Accuracy: ±0.5 psi for range “0”

±1 psi for range “1”

±8% typical for ranges “2” to “7”

Switch: SPDT snap action; single circuit

Features: Barksdale’s Series 9048 Sealed Piston Pressure Switches offer extremely long life in a robust package, making them the ideal solution to your industrial pressure control needs. Sealed Piston switches are ideal for applications demanding rapid cycling at high pressure. Available in various pressure ranges up to 12,000 psi, piston switches are suitable for use in industrial applications such as hydraulic presses, compactors, and machine tools. All models feature a durable, anodized aluminum enclosure with an integrated ½” NPS conduit connector, a tamper-resistant setpoint adjustment screw, and are rated to NEMA 13 as a standard. For applications requiring a highly accurate switch in a durable package, Barksdale’s Series 9048 Sealed Piston Pressure Switches are the ideal choice.

Electrical Characteristics: All models incorporate Underwriters Laboratories, Inc. and CSA Listed single pole double throw snap-action switching elements

Accuracy: ± 2% of the adjustable range

Single pole double throw (SPDT) snap action; single circuit

10 Amps @ 125, 250, or 480 VAC;

0.03 Amps @ 250 VDC (Class B limit switch)

Switches - Temperature, Explosion Proof

Features: Barksdale’s L1X, T1X & T2X Series Temperature Switches provide unmatched performance, quality & reliability in a mechanical thermostat – a safe solution for hazardous locations. The single set point L1X & T1X and dual set point T2X, can switch, measure & control temperatures from 50° to 650°F (-45° to 343°C), and meets Class 1, Div. 1 & 2 hazardous location requirements. The optional adjustable differential provides precise control. These switches can be mounted locally for control directly at the source or remotely up to 25 feet. The L1X, T1X & T2X Series are electrically rated for 10 amps @ 125/250 VAC & 3 amps @ 480 VAC. Standard 3 & 6 pin terminal strips simplify installation. The L1X, T1X & T2X Series are rated NEMA 4, 7 & 9 and incorporate stainless steel temperature sensors to handle a wide range of media. Optional thermowells allow the sensor to work in pressurized vessels to 5000 psi. The L1X, T1X & T2X Series are UL listed & CSA approved & ATEX Certified for hazardous zones within the European Community.

Accuracy: ±1% of mid-60% of full range. At constant ambient +/- 0.5% of full scale.

Switch:

Single Setting:

Dual Setting:

One (1) single pole double throw (SPDT) circuit.

Two (2) independent single pole double throw (SPDT) circuits.

Electrical Characteristics: All models incorporate Underwriters’ Laboratories, Inc. and CSA listed single

pole double throw snap-action switching elements. Switches may be wired normally open or normally closed.

Wetted Parts: 304 stainless steel

Electrical Connection:

Single: 3-pin terminal strip

Dual: 6-pin terminal strip

Electrical Ratings: AC value at 75% power factor —10 amps

125, 250 volts AC, 3 amps 480 volts AC.

Automatically reset by snap-action of switch.

Enclosure/Housing: Designed for hazardous locations: Class I, Division 1 & 2

NEMA 4, 7, 9 & IP65 tamper-proof external adjustment, enclosed terminal strip.

Features: Barksdale’s explosion proof compact temperature switches are ideal for hazardous location and heavy industrial applications where space is a premium and the customer needs a compact and rugged design, UL and CSA Class 1 Div 1, and ATEX approvals, and easy set point adjustment. Paired with the 9681X and 9692X pressure switches, Barksdale offers a complete and reliable solution for your mission critical applications.

Accuracy: 63% of full scale

Typical Life: 1 million cycles

Switch: SPDT, snap action, Class EE, simulated DPDT (optional)

Electrical Ratings: 11 amps @ 125/250 VAC 5 amps @ 30 VDC (EE class)

Materials:

Bulb, Capillary & Armor:

Enclosure:

Local Mount Element:

316 stainless steel

316 stainless steel

300 series stainless steel

Electrical Connection: 1/2 inch NPT male conduit connection 18 AWG, 18” (300 mm) free leads

Enclosure Ratings: NEMA 4X, 7 & 9

Features: Barksdale’s TXR & TXL Series Temperature Switches add flexibility to Barksdale’s solid reputation for quality & reliability and offer versatility for your temperature switching needs. These thermostats are ideal for freeze protection or temperature control in hazardous applications. The TXR & TXL Series thermostats feature 10 foot stainless steel sensors for remote monitoring and local mount sensors for ambient temperature sensing. The TXR & TXL Series feature limit switches with 22 amps @ 125/250 VAC and 3 amps @ 480 VAC electrical ratings that allow thermostats to be used for higher current, heat tracing applications. The TXR & TXL Series models are all UL listed & CSA approved and ATEX certified for use in hazardous zones within the European Community.

Accuracy: ±1% of full scale

Switch:

Type:

Rating: Single pole double throw (SPDT), prewired snap action 22 amp @ 125/250/480 VAC

Electrical Characteristics: All models incorporate Underwriters’ Laboratories, Inc. and CSA listed single

pole double throw snap-action switching elements. Switches may be wired normally open or normally closed.

Electrical Connection: 3/4” NPT female conduit connection. 3 pole terminal block accepts 16-10 AWG

wire.

Enclosure Ratings: NEMA 4, 7, 9, & IP65

Enclosure/Housing: Anodized aluminum, explosion proof, painted silver

Switches - Temperature, General Purpose

Features: Barksdale’s ML1H & L2H Series Temperature Switches provide unmatched performance, quality & reliability in a mechanical thermostat. The single set point ML1H and dual set point L2H, can switch, measure & control temperatures from -50° to 450°F (-45° to 232°C), while the optional adjustable differential provides precise control. These locally mounted switches provide fast response and accurate measurements at the temperature source. Both the ML1H & L2H Series are electrically rated for 10 amps @ 125/250 VAC & 3 amps @ 480 VAC. Standard 3- & 6-pin terminal strips simplify installation. The ML1H & L2H Series are rated NEMA 4 & 13; the optional NEMA 4X construction protects the rugged die-cast aluminum enclosure from corrosive environments. Copper or stainless steel temperature sensors are available to handle a wide range of media. Optional thermowells allow the sensor to work in pressurized vessels to 5000 psi. UL listed & CSA approved, ML1H & L2H Series Temperature Switches are perfect for your temperature sensing needs.

Accuracy: ±1% of mid-60% of full range. At constant ambient ±0.5% of full scale.

Switch: Single: 1 SPDT

Dual switching: 2 independent SPDT circuits

Electrical Characteristics: All models incorporate Underwriters’ Laboratories, Inc. and CSA listed single

pole double throw snap-action switching elements. Switches may be wired normally open or normally closed.

Wetted Parts: Brass or 304 stainless steel

Electrical Connection:

Single: 3-pin terminal strip

Dual: 6-pin terminal strip

Electrical Ratings: AC value at 75% power factor —10 amps 125, 250 volts AC, 3 amps 480 volts AC.

Automatically reset by snap-action of switch.

Enclosure/Housing: Water-tight and dust-tight indoor and outdoor (NEMA 4) / oil-tight and dust-tight

indoor (NEMA 13).

Local Mount: Immersion length 2-1/16 inches

Features: Barksdale’s MT1H & T2H Series Temperature Switches provide unmatched performance, quality & reliability in a mechanical thermostat. The single set point MT1H and dual set point T2H, can switch, measure & control temperatures from -50° to 650°F (-45° to 343°C), The optional adjustable differential provides precise control while ambient compensation maintains 1/2% accuracy with external temperatures from -65° to 165°F. The MT1H & T2H Series are electrically rated for 10 amps @ 125/250 VAC & 3 amps @ 480 VAC. Standard 3- & 6-pin terminal strips simplify installation. The MT1H & T2H Series are rated NEMA 4 & 13; the optional NEMA 4X construction protects the rugged die-cast aluminum enclosure from corrosive environments. A remote bulb and capillary sensor is available in copper or stainless steel allowing the switch to be mounted up to 25 feet from the temperature source. Optional thermowells allow the sensor to work in pressurized vessels to 5000 psi. UL listed & CSA approved, MT1H & T2H Series Temperature Switches are perfect for your temperature sensing needs

Accuracy: ±1% of mid-60% of full range. At constant ambient ±0.5% of full scale.

Switch: One (1) SPDT or two (2) independent SPDT circuits

Electrical Characteristics: All models incorporate Underwriters’ Laboratories, Inc. and CSA listed single

pole double throw snap-action switching elements. Switches may be wired normally open or normally closed.

Wetted Parts: Copper or 304 stainless steel

Electrical Connection:

Single: 3-Pin terminal strip

Dual: 6-Pin terminal strip

Electrical Ratings: AC value at 75% power factor —10 amps @ 125, 250 volts AC, 3 amps @ 480 volts

AC. Automatically reset by snap-action of switch.

Enclosure/Housing: Watertight and dust-tight indoor and outdoor (NEMA 4)/oil-tight and dust-tight

indoor (NEMA 13).

Transmitters - High Pressure

Features: Lightweight, compact and all-welded rugged stainless steel construction Thin-film & diffused silicon sensors for high accuracy

Optional HART® communication protocol with diagnostics & field calibration, reducing maintenance time and cost; and 10:1 turndown ratio for rangeability, maintaining high accuracy and allowing one part for multiple pressure ranges

Available pressure ranges up to 30,000 PSI

High accuracy down to 0.1% FSO, LHR

cULus, ATEX, IECEx and Single Seal certifications

Explosion proof enclosure with IP66 / IP67 and NEMA 4X, 7 & 9 ratings CE, CRN, NORSOK and NACE compliant and Superior EMI, ESD and RFI protection

Factory sealed, environment friendly, halogen free wires and cable

Transmitters - Pressure

Features: Lightweight, compact and all-welded rugged stainless steel construction Thin-film & diffused silicon sensors for high accuracy

Optional HART® communication protocol with diagnostics & field calibration, reducing maintenance time and cost; and 10:1 turndown ratio for rangeability, maintaining high accuracy and allowing one part for multiple pressure ranges

Available pressure ranges up to 30,000 PSI

High accuracy down to 0.1% FSO, LHR

cULus, ATEX, IECEx and Single Seal certifications

Explosion proof enclosure with IP66 / IP67 and NEMA 4X, 7 & 9 ratings CE, CRN, NORSOK and NACE compliant and Superior EMI, ESD and RFI protection

Factory sealed, environment friendly, halogen free wires and cable

Features: Barksdale’s 440 Series Intrinsically Safe Transducers provide high accuracy pressure measurement when operating in Class I, Division I environments. Intrinsically safe transducers prevent personal injury and machinery damage by preventing the explosion in the first place. External zener barriers are required in order to meet UL requirements for an intrinsically safe installation. The higher cost of having to install a zener barrier is offset with the comfort of knowing that an explosion will not occur within normal operating conditions. Three models are available: Series 443 (0-5V), Series 445 (4-20mA) and Series 446 (0-10V).

Accuracy (LH & R): ±0.25% FSO at 75°F (±0.5% for vacuum only [-23]) typical

Long Term Stability: ±0.5% FSO of calibration curve

Typical Life Cycle: 100 million cycles

Proof Pressure: 2 times rated pressure or 13,000 psi max. (884 bar), whichever is less

Series 445

• Excitation voltage: 12 to 28 VDC

• Output: 4 to 20 mA

• Full scale output: 16 mA ± 1%

• Zero output: 4 mA ± 2%

Transmitters - Pressure, Explosion Proof

Features: Lightweight, compact and all-welded rugged stainless steel construction Thin-film & diffused silicon sensors for high accuracy

Optional HART® communication protocol with diagnostics & field calibration, reducing maintenance time and cost; and 10:1 turndown ratio for rangeability, maintaining high accuracy and allowing one part for multiple pressure ranges

Available pressure ranges up to 30,000 PSI

High accuracy down to 0.1% FSO, LHR

cULus, ATEX, IECEx and Single Seal certifications

Explosion proof enclosure with IP66 / IP67 and NEMA 4X, 7 & 9 ratings CE, CRN, NORSOK and NACE compliant and Superior EMI, ESD and RFI protection

Factory sealed, environment friendly, halogen free wires and cable

Features: Barksdale’s 420X Series Explosion Proof Transducers prevent an explosion from occurring when operated in a Division 1 environment. Barksdale’s 420X Series transducers prevent personal injury and machinery damage by preventing the explosion the first place. Energy generated within the transducer is of such a low level that intermittently present flammable vapors will not be ignited. External zener barriers are not required in order to meet UL requirements for a non-incendive installation. The lower cost of not having to install zener barriers means that the positive aspects of intrinsically safe and explosion proof are combined in Barksdale non-incendive transducers. Three models are available: Series 423X (0-5V), Series 425X (4-20mA) and Series 426X (0-10V).

420X Series Transducers:

• Explosion Proof

• NEMA 4X for environmental protection

• NEMA 7 & 9 for explosion proof protection

• No zener barrier means simpler installation and lower cost

• UL & C-UL Listed

Transmitters - Pressure, General Purpose

Features: Barksdale’s Series 423 and 426 Transducers and 425 Transmitters are general purpose, industrial grade transducers, ideal for use in general industrial applications when a robust transducer is required. Wetted parts are constructed of 17-4PH and 300 Series Stainless Steel, with NEMA 4 enclosures constructed of 304 Stainless Steel. These units feature a stable, diffused silicon sensor that achieves .25% accuracy, have pressure ranges from 0-10,000 psi and are available in 5V, 10V or 4-20 mA outputs. High pressure snubbers are standard on units at 2,000 psi and above. Optional surge voltage protection to 6kV is available. A variety of process fittings and electrical connections are available to meet your needs.

Accuracy (LH & R): ±0.25% BSL

Long Term Stability: ±0.5% FSO of calibration curve

Typical Life Cycle: 100 million cycles

Proof Pressure: 2 times rated pressure or 13,000 psi max. (884 bar), whichever is less

Input:

425: Excitation voltage: 12 to 32 VDC

Supply Current: 15 mA maximum (no load)

Min. Load Resistance: 2K ohms (voltage series only)

Output:

425: Output: 4 to 20 mA

Full scale output: 16 mA ± 0.4%

Zero output: 4 mA ± 0.2%

Features: Barksdale’s 430 Series Non-IncendiveTransducers prevent an explosion from occurring when operated in a Division II environment. Barksdale’s 430 Series, non-incendive transducers prevent personal injury and machinery damage by preventing the explosion in the first place. Energy generated within the transducer is of such a low level that intermittently present flammable vapors will not be ignited. External zener barriers are not required in order to meet UL requirements for a non-incendive installation. Three models are available: Series 433 (0-5V), Series 435 (4-20mA) and Series 436 (0-10V).

Accuracy (LH & R): ±0.25% FSO at 75°F (±0.5% for vacuum only [-23]) typical

Long Term Stability: ±0.5% FSO of calibration curve

Typical Life Cycle: 100 million cycles

Proof Pressure: 2 times rated pressure or 13,000 psi max. (896 bar), whichever is less

Input:

435:

Excitation voltage: 12 to 28 VDC

Output:

435: Output: 4 to 20 mA

Full scale output: 16 mA ± 1%

Zero output: 4 mA ± 2%

Transmitters - Pressure, Intrinsically Safe

Features: Barksdale’s 440 Series Intrinsically Safe Transducers provide high accuracy pressure measurement when operating in Class I, Division I environments. Intrinsically safe transducers prevent personal injury and machinery damage by preventing the explosion in the first place. External zener barriers are required in order to meet UL requirements for an intrinsically safe installation. The higher cost of having to install a zener barrier is offset with the comfort of knowing that an explosion will not occur within normal operating conditions. Three models are available: Series 443 (0-5V), Series 445 (4-20mA) and Series 446 (0-10V).

Accuracy (LH & R): ±0.25% FSO at 75°F (±0.5% for vacuum only [-23]) typical

Long Term Stability: ±0.5% FSO of calibration curve

Typical Life Cycle: 100 million cycles

Proof Pressure: 2 times rated pressure or 13,000 psi max. (884 bar), whichever is less

Series 445

• Excitation voltage: 12 to 28 VDC

• Output: 4 to 20 mA

• Full scale output: 16 mA ± 1%

• Zero output: 4 mA ± 2%