Control Air is a leading manufacturer of precision air pressure and air filter regulators, transducers, valve positioners, air relays, volume boosters and frictionless diaphragm air cylinders, and offers worldwide distribution with excellent service and outstanding technical support.

Control Air assures product availability and on-time delivery thanks to their streamlined manufacturing process. The company specializes in strategic alignment partnerships to customize products to meet specific requirements.

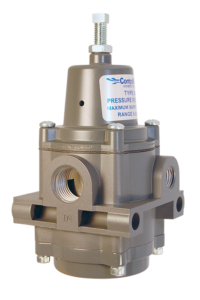

Back Pressure Regulator

Features: The Type-700BP Back Pressure Regulator is a high flow, highly accurate pneumatic relief valve with an adjustable set point. It’s primary function is to provide protection against over pressurization in the downstream portion of a pneumatic system. This precision unit is capable of handling flows up to 50

SCFM. A rolling diaphragm provides the sensitivity that causes the Type-700BP to vent to atmosphere in response to the slightest upstream changes.

Flow Capacity . . . . . . . . . . . . . . . . . . . . . . . Up to 50 SCFM (85 m3/hr) depending on set point pressure and port size.

Sensitivity . . . . . . . . . . . . . . . . . . . . . . . . . . 1/8″ (3.2 mm) water

Maximum System Pressure . . . . . . . . . . . . .250 psig (1725 kPa)

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . Pipe or Panel

Ambient Temperature . . . . . . . . . . . . . . . . . 0°F to 150°F

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.5 lb (.68 Kg)

Low Pressure Regulators (up to 3,500 PSI)

Features: The Type 330/340 Series of Instrument Air Filter Regulators and Regulators are designed to provide clean, accurate air pressure to instruments, valves, and other automatic control equipment in a lightweight, compact housing. These quality instruments are constructed of durable materials that will provide long lasting performance in industrial environments.

In/Out Port Size 1/4″ NPT 1/2″ NPT (Gauge Ports 1/4 NPT)

Output Ranges 0-30 psig (0-2BAR) 0-60 psig (0-4 BAR) 0-120 psig (0-8 BAR)

Maximum Supply Manual drain: 250 psig (17 BAR)

Pressure Auto drain: 150 psig (10 BAR)

Mounting Pipe, bracket or through body direct

Filter 40 micron (5 optional)

Cv Values 0.5 at 150 psig supply and 2.5 at 150 psig supply and 80 psig setpoint

Exhaust Capacity 0.1 scfm (2.83 Nl/min) with downstream pressure 5 psig (0.3 BAR) above set point

Sensitivity 1″ of water

Air Consumption Less than 5 scfh (2.5 Nl/min)

Effect of Supply Pressure Variation Less than 0.25 psig (0.017 BAR) for 25 psig (1.7 BAR) change

Temperature Limits Manual drain: 0° to 160° F (-18° C to 71° C) Auto drain: 32° to 160° F (0° C to 71° C)

Operating Media Air, Inert Gas and Sweet Natural Gas

Features: The Type 350/360/370SS series of stainless steel regulators, filter regulators and filters are designed to stand up to the harshest environments while providing highly accurate pressure regulation. Proven 316 stainless steel housing and filter assemblies along with fluorocarbon elastomers make the 350/360/370SS compatible with sour gas and adaptable to off shore environments. These quality instruments are economical to buy as well as operate, and provide extremely stable and repeatable control of gas pressure. Oversized valving helps the units achieve high flow rates with minimal pressure drop.

Output Ranges: 0-30 psig (0-2.0 BAR), 0-60 psig (0-4.0 BAR), 0-100psig (0-7.0 BAR), 0-150 psig (0-10.0 BAR)

Exhaust Capacity: 1.0 SCFM (1.7 m3/hr) at downstream pressure of 10 psig (0.7 BAR) above set point

Maximum Supply Pressure: 290 psig (20.0 BAR)

Air Consumption: 4 SCFH (0.1 m3/hr) maximum

Operating -20° to +185° F (-29° C to +85° C)

Temperatures: Low Temperature Option: -58° to +194° F (-50° to + 90° C)

Filter: 25 micron optional 5 micron filter (where applicable)

Porting: Inlet/Outlet: 1/4″ NPT or 1/2″ NPT

Gauge (2): 1/4″ NPT

Exhaust: 1/8″ NPT

Materials: AISI 316 stainless steel: body, bonnet, filter

Fluorocarbon: diaphragm, seals

Silicone: diaphragm, seals (low temperature option)

Inconel: range spring, pintle spring

Features: The Type 380/390SS stainless steel filter regulator series is designed for demanding applications that

require stable, accurate pressure regulation and high flow capacity. Corrosion resistant 316L stainless steel housing, trim and filter assemblies make this series adaptable to offshore and other harsh environments. Large porting ensures stable and repeatable output pressures, even during wide supply pressure variations from large volume valve actuators. Oversized valving helps the units achieve high flow rates with minimal pressure drop.

Output Range 0-30 (0-2), 0-60 (0-4), 0-100 (0-7), psig (bar) 0-150 (0-10), 0-200 (0-14)

Maximum Supply 290 psig (20.0 BAR)

Pressure Autodrain: 150 psig (10 BAR)

Maximum Flow Type-380: 3/4″: 9.0; 1″: 10.0

Coefficients (Cv) Type-390: 3/4″: 10.0; 1″: 11.0

Exhaust Capacity 2.0scfm (56.5 NL/min), downstream pressure 10 psig (0.7 bar) above set point

Air Consumption 4 scfh (2 NL/min) maximum

Operating -40°F to +200°F (-40°C to +93°C)

Temperatures Autodrain: 32°F to 200°F (0° to 93°C)

Operating Media Air, inert gas, sweet (natural gas)

Porting Inlet/Outlet: 3/4″ NPT or 1″ NPT

Gauge (2): 1/4″ NPT

Exhaust: 1/8″ NPT

Filtration Type-380: 40 micron standard or 5 micron option

Type-390: N/A

Weight Type-380: 16.6 lbs (7.5 kg)

Type-390: 14.5 lbs (6.6 kg)

Materials 316L stainless

steel: body, bonnet, filter

Nitrile: diaphragm, seals

Inconel: valve spring

Features: The Control Air Type 400 is a general purpose regulator designed to provide reliable performance under variable operating conditions. This quality unit is ideal as an economical alternative for control of industrial process applications. The regulation characteristics of the Type 400 have been proven to be superior to comparable competitive units. Durable materials and corrosion resistant construction provide reliable operation in harsh industrial environments.

Flow Capacity 20 SCFM (570 Nl/min) at 100 psig (6.8 BAR) suåpply – 20 psig (1.4 BAR) outlet

Exhaust Capacity 0.1 SCFM (2.8 Nl/min)-downstream pressure 5 psig (0.3 BAR) above set point

Sensitivity 1″ (2.5 cm) of water

Effect of Supply Less than 0.2 psig (0.01 BAR)

Pressure Variation for 25 psi (1.7 BAR) change

Max. Supply Pressure 250 psig (17 BAR)

Air Consumption Less than 6 SCFH (170 Nl/min)

Output Range 0-10 psig (0-0.7 BAR), 0-30 psig (0-2 BAR), 0-60 psig (0-4 BAR), 0-120 psig (0-8 BAR)

Port Size 1/4″ NPT

Features: The ControlAir Type 850 and Type 860 are compact units that provide low-cost, high performance

pressure regulation of compressed air (Type 850 and Type 860) or water (Type 860). Designed specifically for the OEM market, these units are ideal for compressed air or water pressure control applications. The highly sensitive diaphragmoperated design delivers accurate downstream pressure by

eliminating the problems caused by sticking in piston designs utilized by competitors. A molded rubber supply valve provides accurate regulation and helps prevent leakage.

Type 850: Compressed Air 860: Compressed Air or Water

Flow Capacity 24 scfm (48 m3/hr) at 100 psig (6.9 BAR) supply, 60 psig (4.1 BAR) output

Relief Capacity (Type 850) 0.5 scfm (.85 m3/hr)

Downstream pressure 10 psig (0.7 BAR) above setpoint

Maximum Supply

Pressure 250 psig (17.2 BAR)

Air Consumption Less than 6 scfh (0.17 m3/hr)

Operating

Temperature 0°F to 150°F (-18°C to 60°C)

Porting Inlet and outlet-1/8″ or 1/4″ NPT

Gauge (2) – 1/8″ NPT

Output Ranges 0-5 psig (0-0.4 BAR) 0-60 psig (0-4.1 BAR)

0-15 psig (0-1.0 BAR) 0-100 psig (0-6.9 BAR)

0-30 psig (0-2.1 BAR)

Materials Body-zinc, bonnet-acetal, diaphragm/seals-nitrile, internals-aluminum, brass, acetal, steel, music wire (Type 860 is plated with electroless nickel for water use)

Medium Pressure Regulators (up to 6,000 PSI)

Features: The Type 3500 provides a low cost, dependable regulator to reduce inlet pressures from as high as 6000 psig (413 BAR) down to working pressures ranging between 0 and 225 psig (15.5 BAR). This first cut regulator is available in three separate spring ranges. These versatile devices can be used as pilot supply or pressure loading regulators where a high-pressure operating valve must be controlled by a gas regulator pilot. The Type 3500 is designed for use with noncorrosive gases.

Inlet Port 1/4″ NPT

Outlet Ports (3) 1/4″ NPT

Output Ranges 0-125 psig (0-8.6 BAR), 0-150 psig (0-10.3 BAR),

and 0-225 psig (0-15.5 BAR)

Supply Pressure 6000 psig (413 BAR) Maximum

Temperature Range -70° to 225° F (-57° to 107° C)

Pressure Transducers

Features: The Type-950XP Explosion-proof I/P (current to pressure) transducer produces a pneumatic output that is directly proportional to a current input signal. A closed loop pressure feedback control system provides a highly accurate, stable air pressure output for the operation of actuated valves. The unit can mount in any position and is vibration insensitive. Its compact housing and easily accessible ports and adjustments make set-up and installation of the unit simple. An integral volume booster provides high flow capacity, which increases control speed in critical applications.

Inputs 4-20 mA

Outputs 3-15 psig 0.20-1.00 BAR

3-27 psig 0.20-1.80 BAR

6-30 psig 0.40-2.00 BAR

Air Consumption 3.0 scfh (0.11 m3/hr) at mid range

Supply Pressure 100 psig (7.0 BAR) maximum

Note: Supply pressure must be a minimum of 5 psig above maximum output

Flow Capacity 4.5 scfm (7.6 m3/hr) at 25 psig (1.7 BAR) supply

12.0 scfm (20.0 m3/hr) at 100 psig (7.0 BAR) supply

Temperature Limits Operating -40° to +160° F (-40° to +71° C)

Storage -40° to +200° F (-40° to +93° C)

Loop Load, I/P Transducer 10.0 VDC @ 20 mA

Operating Modes direct, reverse and split range

(Split ranging not possible with field selectable option)

Features: The ControlAir Type 500X converts a current or voltage input signal to a linearly proportional pneumatic output pressure. This versatile instrument is designed for control applications that require a high degree of reliability and repeatability at an economical cost. Optional NEMA 4X (IP65) version allows for splashdown and outdoor installation.

Min./Max. Supply Pressure

Minimum – 3 psig (.21 BAR)

Above maximum output

Maximum – 100 psig (7 BAR)

Supply Pressure Sensitivity

<± 0.1% of span per psig

(<± 0.15% of span per 0.1 BAR)

Terminal Based Linearity

<± 0.75% of span

Repeatability

< 0.5% of span

Hysteresis

< 1.0% of span

Flow Rate

4.5 scfm (7.6 m3/hr ANR) at 25 psig (1.7 BAR) supply

Maximum Air Consumption

.05 scfm (.07 m3/hr) midrange typical