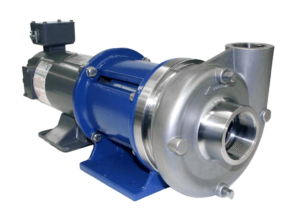

Centrifugal Pump

Features: Liquiflo’s Centry® Pumps are Sealed and Magnetically-Coupled (MC) centrifugal pumps engineered and manufactured for the user with increased needs for equipment reliability. These pumps are specifically designed to handle the lower flow applications that create maintenance problems for standard ANSI pumps operating at less than BEP. The Centry Series pumps can handle flows up to 160 GPM and heads up to 100 ft.

They are available in 316 Stainless Steel or Alloy-C* constructions, and with threaded or flanged port configurations.

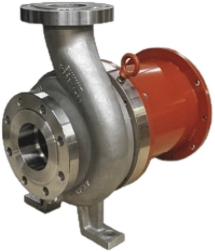

Features: Liquiflo’s Endura® Pumps are Group I & Group II ANSI-Dimensional Magnetically-Coupled (MC) centrifugal pumps. These pumps were designed to meet the demanding needs of the chemical processing industry and will also handle many challenging pumping applications, such as those which require dry-running, pumping slurries or high-temperature demands. The Endura Series pumps cover flows up to 770 GPM and heads up to 420 ft.

They are available in 316 Stainless Steel or Alloy-C* constructions, and with flanged port configurations.

Electric Driven Pumps

Features: The Harrier+ controller allows for full chemical injection automation. It unlocks features and capabilities that allow you to optimize your chemical usage saving you time and money!

The controller works by controlling the injection rate via timing, cycle count, or flow control. The adaptive injection rate controls provide an accuracy of +/- 1%. The controllers use sensors along with Graco software to adjust to changes in the application such as well pressure or battery voltage. It also controls and monitors your system remotely with a cellular connection and web app. The remote connectivity allows you to monitor, control and calibrate your system via cellular or SCADA connection (Modbus). The Harrier+ controller can be made available as a standalone controller or in the power box & control panel kits.

The controller is classified for hazardous location Class 1, Divison 2, Groups A, B, C, D, T4.

The Harrier+ will provide a noticeable ROI via chemical savings, power-saving, and low cost of ownership.

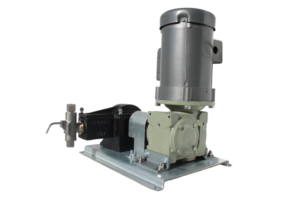

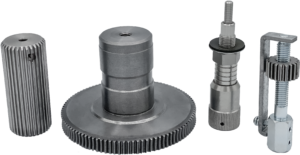

Features: Flomore Series 3500 chemical injection pumps are electric driven, positive displacement pumps utilizing C-faced motors and common gear reducers. The gear reducers are available in 15, 30, 60, and 120 strokes per minute configurations. By utilizing even further flexibility of a wide variety of plunger sizes, the Series 2500 can fill many application requirements of different flows and pressures.

The Series 3500 can have up to four, flow adjustable heads while running fluid ends.

OPTIONS: Ceramic plungers, which provide longer packing life, and a wide variety of packing are designed to meet the demands of many different chemical applications.

■ Maximum discharge pressure: 6,000 psi (414 bar) with 3/16” plunger

■ Maximum volume 139 gallons per day per head (528 liters per day) with 1/2” plunger

■ Each head is adjustable while running

■ Available simplex, duplex, triplex, or quadruplex configurations

■ Mix or match head sizes – pump the same or different chemicals

■ Available in four-stroke rates: 15, 30, 60, or 120 strokes per minute

■ Each head is independently coupled and easy to maintain in the fi eld

■ 1 or 3 phase, TEFC or explosion-proof, 50 or 60 Hz motors available

■ Available with 3/16”, 1/4”, 3/8”, or 1/2” plunger

| Head Size | Model | PSI | Volume Range LPD |

|---|---|---|---|

3/16″ |

35H4 |

6,000 |

0.76 to 9.08 |

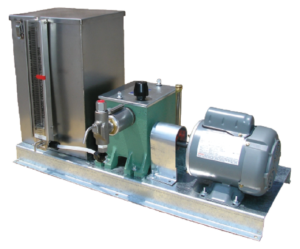

Features: The Series 4400 pump utilizes an integral worm gear drive available in three different standard ratios and six plunger sizes to provide a wide selection of flows and pressures.

■ Positive Displacement

■ Up to 8 pumping heads driven by a single motor

■ Each pumping head capacity is fi eld adjustable 0 to 100% while running

■ Oil bath lubrication for long gear box life

| Head Size | Model | Pressure | Volume Range LPD |

|---|---|---|---|

3/16″ 1/4″ 3/8″ 1/2″ 3/4″ 1″ |

4424 |

5,000 |

0.24 to 9.46 |

Features: The Wolverine™ Hazardous Location pumps are designed to operate in applications requiring Class 1, Division 1, rated products. They have 316 SST wetted parts, plus they’re resistant to water and dust.

Flow rates up to 1,211 LPD and a pressure rating up to 10,000 PSI. Precision stroke adjustment between 1/2″ to 1″ ensures accurate injection rates. HNBR, FKM, FKM-ETP, and FFKM plunger packings and check valve seals can handle some of the most aggressive chemicals. The AC and DC operated motors are rated for use in Division 1 Hazardous (Classified) Locations per the following standards: Class 1, Div 1, Group C & D.

Features: The variable speed Wolverine pump provides continuous injection for an even dispersion of chemicals. Flow rates are adjusted between 10 and 100% by a control dial on the motor eliminating the need for a localized controller. The fluid heads are interchangeable between all Wolverine Advanced series pumps. High efficiency 12 or 24VDC brushless motors use less amperage draw than traditional brushed DC motors. It can be integrated with the Harrier+ and alternative energy sources for a fully automated, green pump.

Available in simplex or duplex configuration with flow rates from 2 LPD up to 370 LPD (based on configuration), and pressures ranging from 600 PSI to 10,000 PSI.

Class 1, Div 2, Groups A, B, C, D.

Features: G-Chem Series pumps are ideal for chemical injection applications. They are easy to operate and far exceed the performance of similar pumps of its class. Available in AC and DC power configurations and can be paired with the Harrier Controller. Available sizes from 1/4″ to 1/2″ with flow rates from 8 GPD to 66 GPD and pressures from 800 to 2500 PSI. Fluid ends are stainless steel and offered with Chromex™ coated plungers making it a preferred choice for a wide variety of chemical applications.

Features: The Graco G-JR is an ideal chemical injection pumping solution that has been engineered to offer reliable chemical dosing at a low cost. Offered in DC solar or AC electric, the pumps come standard with the Harrier™ EZ-JR controller which offers a similar set of features as the current Harrier EZ controller.

The simple design has a single plunger size with a maximum output of 30.3 LPD at 2000PSI. It is ideal for a low-cost automatable solution.

Features: The Mongoose Series metering pump is ideal for dispensing chemicals for a variety of diverse markets such as oil and natural gas, mining, agriculture, landscaping, and lawn maintenance, waste water, and car wash. These pumps can also be used in chemical dosing maintenance applications including cooling towers, boilers, and plating, as well as a multitude of other uses.

Stainless Steel head, PEEK and PTFE diaphragm, and seal material can be used in a host of chemical applications. Flow rates range from 17 GPD to 45 GPD and pressures of 75 PSI to 250 PSI.

Features: The Graco Multipoint injection system allows you to control up to 8 injection points using a single pump and controller. Set, change, and remotely monitor the individual flow rates of each injection point to help reduce the number of trips to the well site and minimize downtime. Receive alarm notifications on your phone, computer, or smart device if any disruptions in operation occur.

The Harrier+ MPI Controller features Smart Logic for solenoid failure detection. The system will continue to operate while servicing a solenoid valve to help minimize downtime. In the event of a solenoid failure, alarms will identify which one needs replacement. The controller activates one valve at a time for maximum dosing efficiencies.

The KRAKN MPI replaces up to eight chemical pumps with just one when used in conjunction with the KRAKN MPI fluid manifold. Pair it with Graco’s Harrier+ MPI control box and chemical pumps for best dosing accuracy. It is available from 2 up to 8 injection points, 316 Stainless Steel construction rated for 3000 PSI (345 Bar), using FFKM seals, and is C1D1 and GP.

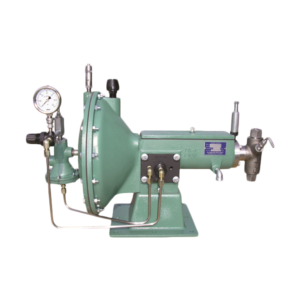

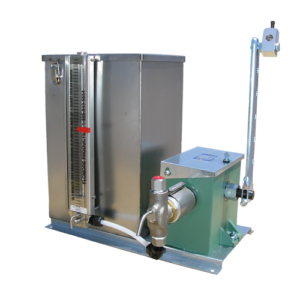

Features: The Series 3400 electric driven injection pump utilizes C-faced motors and common gear reducer available in two speeds of 30 or 60 strokes per minute.

■ Maximum discharge pressure: 4,000 psi (276 bar) with 1/2” plunger

■ Maximum volume: 1760 GPD (6,662 Liters) with 1-1/4” plunger

■ Simplex, duplex or quad configuration

■ 1 or 3 phase – TEFC or explosion-proof motors available

■ Plunger sizes: 1/2”, 3/4”, 1”, 1-1/4”

■ Flow adjustable while running with adjustable crosshead

| Head Size | Model | PSI | Volume Range LPD |

|---|---|---|---|

3/16″ |

34G4 |

7,500 |

3.71 to 37.1 |

Gear Pumps

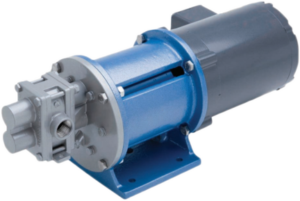

Features: The H-Series Gear Pumps were designed as an upgrade to Liquiflo’s original 3-Series. With similar outside dimensions and capacities, the H-Series incorporates larger diameter shafts and bearings, allowing them to handle higher pressures with extended service life. H-Series pumps are available in Sealed and Mag-Drive versions with flows up to approximately 55 GPM and differential pressures up to 225 PSI with 300 PSI possible on some models.

Flows up to 55 GPM

Differential Pressures up to 225 PSI

Viscosities from 0.3 to 100,000+ cP

316 SS or Alloy-C Basic Construction

Packing, Single Mechanical Seal, Double Mechanical Seal or Mag-Drive

Closed-Coupled or Long-Coupled

12 Models Offered

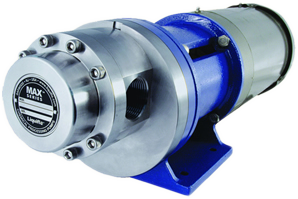

Features: The Max® Series Gear Pumps feature helical gears and relieved wear plates for smoother and quieter operation and intrinsic reduction of gear separation forces. Their unique and durable design will ensure extended life in high-pressure pumping applications.

Flows up to 20 GPM

Pressures up to 350 PSI

316 SS or Titanium

9 Models Offered

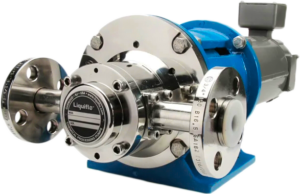

Features: The Poly-Guard® Series Gear Pumps were designed to handle the most corrosive chemicals, such as inorganic acids, alkalis and salts. All internal components and surfaces are non-metallic, which makes the Poly-Guard pump an excellent choice for high-purity services.

Flows up to 25 GPM

Pressures up to 100 PSI

303 SS/PFA-Lined

9 Models Offered

High Temperature Pumps

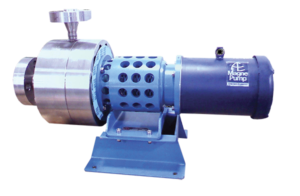

Features: Parker Autoclave Engineers MagnePumps eliminate or reduce many of the problems associated with conventional pumps, such as leakage, contamination and packing heat generation. They are ideal for applications where purity of the fluid is a major consideration or where leakage of material could be hazardous such as nuclear and petrochemical hydrates loops. In addition, power loss is eliminated due to no seal friction, delivering full motor horsepower to the pumping unit. Also, when adverse conditions exist the magnet drive functions as a clutch, eliminating overload and motor burnout.

| 3/4 and 1-1/2 HP | 5 and 7-1/2 HP | |

|---|---|---|

MAWP |

5000psi @ 650°F (345bar @ 343°C) |

2500psi @ 650°F (172 bar @ 343°C) or 4400psi @ 600°F (303bar @ 315°C) |

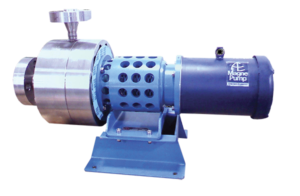

Magnetically Coupled Pumps

Features: Parker Autoclave Engineers MagnePumps eliminate or reduce many of the problems associated with conventional pumps, such as leakage, contamination and packing heat generation. They are ideal for applications where purity of the fluid is a major consideration or where leakage of material could be hazardous such as nuclear and petrochemical hydrates loops. In addition, power loss is eliminated due to no seal friction, delivering full motor horsepower to the pumping unit. Also, when adverse conditions exist the magnet drive functions as a clutch, eliminating overload and motor burnout.

| 3/4 and 1-1/2 HP | 5 and 7-1/2 HP | |

|---|---|---|

MAWP |

5000psi @ 650°F (345bar @ 343°C) |

2500psi @ 650°F (172 bar @ 343°C) or 4400psi @ 600°F (303bar @ 315°C) |

Pneumatic Driven Pumps

Features: Python pumps are ideal for applications that require a pump to operate in a potentially explosive atmosphere and can run off regulated natural gas or compressed air. The Python uses half the air consumption of other pumps in the market. Plus, the Python’s extreme duty plungers, seals, and timing valve are designed for years of operation before replacement.

Pythons are offered with Chromex and Ceramic coated plungers and a standard 316 SST fluid section/wetted parts. HNBR, FKM, FKM ETP, TFEP, and FFKM plunger packings and check valve seals available.

The Python’s proprietary poppet style check valve eliminates the valve from sticking.

The Python is available in flow rates from 6 LPD to 70 LPD and injection pressures of over 10,000 PSI.

Features: The Python XL Series pumps are ideal for wells with low gas pressure – it only requires a minimum of 15 PSI to operate! The pump has a very low air/gas consumption making for increased efficiency. Up to 97% of the exhaust gas is recoverable which makes the Python XL an environmentally friendly pneumatic pump.

Fluid ends are available in 316 SS with multiple packing choices (HNBR, FKM, FKM ETP, FFKM, and TFE/P). Flow rates are available from 379 LPD to approximately 1500 LPD with a pressure range up to 1200 PSI.

Features: Python XL-DA series pumps are suitable for chemical injection applications that require higher flows at high pressures. These pumps operate on low gas or compressed air pressures and utilize the same Merkur® air motor used on other Graco products. With an option gas kit, the pump can recover its exhaust. It is self-priming and double-acting which provides continuous flow operation and prevents the pump from air locking.

Double Acting

• Pumps fluid in both directions of the stroke for increased flows

• Provides continuous flow operation for better pump efficiencies

Self Priming

• Anti-locking so air cannot get trapped inside air motor and stall pump

• Pump can free itself of air and resume pumping without any adjustments

The pump is capable of up to 3000 LPD and pressures up to 6000 PSI.

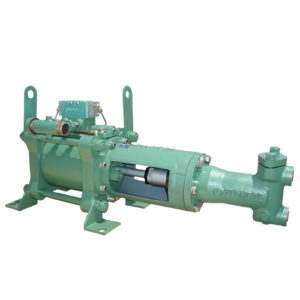

Features: The Series 5020 pump is designed for high flow and high-pressure applications.

■ Pressure as high as 10,000 psi

■ Designed for continuous operation

■ Excellent for pumping chemicals, methanol, and corrosion inhibitors

■ Field adjustable speed/volume control

■ Simple modifi cation can lower pumping rate to one stroke every five minutes

■ Operates with air/gas pressures as low as 15 psi

■ Trim for corrosive applications available

■ Microswitch design available

■ Regulator, gauges, and tanks available as accessories

| Head Size | Model | Pressure | Max GPD (Cont./Int.) |

|---|---|---|---|

1/4″ |

5021 |

12,000 |

16/20 |

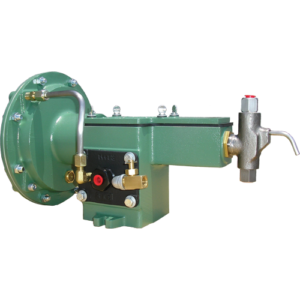

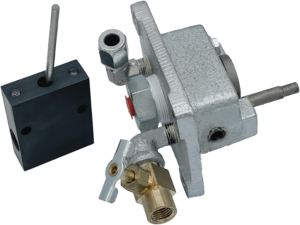

Features: The Series 5200 pump is powered by gas/air via a diaphragm with a spring return. The pump offers two strokes for adjustable 1” or 1/3” lengths and flow rates.

■ Direct acting

■ Powered by diaphragm motor with spring return

■ Field adjustable speed/volume control

■ Operates with air/gas pressures as low as 8 psi

■ Trim for corrosive applications available

■ Micro switch design available

■ Regulators, gauges and tanks available as accessories

| Head Size | Model | Pressure | Max Volume LPD |

|---|---|---|---|

3/16″ |

5204 |

6,000 |

15.90 |

Features: The Series 6200 pump offers the highest flow rate, 20 gallons per minute, all the Flomore chemical injection pumps. This pump is well-suited for offshore applications with its optional three-part corrosive resistant paint system.

■ Positive displacement pump

■ Simplex or duplex offering

■ Field adjustable speed/volume control

■ Exhaust gas can be recovered to minimize gas consumption

■ Heads made from cast steel or 316 stainless steel

■ Minimum NDSHR – 8 feet of water

■ Trim for corrosive applications available

■ Regulators, gauges, and manifold available as accessories

| Head Size | Model | Disch Press | Volume Range GPD |

|---|---|---|---|

1-1/4″ 2-3/4″ 4″ |

6201 6202 6204 |

9,000 |

576 to 2592 |

Pump Parts

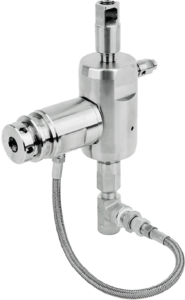

Features: The Graco No-Drip Fluid Ends are designed to eliminate chemical leaks via a flexible hose assembly, helping you to avoid hazardous maintenance and limit environmental impact. The No-Drip Fluid End works harmoniously with Graco pumps and almost all legacy style pumps in the market, offering you a versatile and hassle-free solution.

Features:

• 316 SS Construction: Ensures durability and long-lasting performance.

• Double Packing Stack: Extra protection to guarantee the security of your chemicals.

• Flexible Return Hose: For ease of maintenance.

• Proprietary Graco Check Valve: Unitized, poppet style check valve – an industry-leading feature you can trust.

• Legacy Adapter: Compatibility with competitor pumps to make your transition seamless.

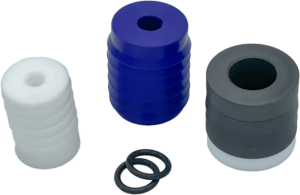

Features: Packing and O-Rings are available in a host of materials to match your chemical compatibility. We heavily stock SDP, Buna, Teflon, Viton, and many others. All of these are available in a variety of sizes to ensure a proper fit for your application.

Packing and O-Rings are fully cross compatible with most major pump brands.

Specialty Pumps

Features: The G-Chem Beam Pump provides reliable and robust means of injecting chemicals by operating with a pumpjack. The G-Chem is a positive displacement plunger-type pump powered by a direct connection with a cable or rod to the pumpjack’s walking beam.

The pump has a maximum flow rate of 75 LPD and pressures up to 25 PSI. The head is 316 SS and can have a variety of seals (FKM, HNBR, and TFE/P).

Features: Designed specifically for operation on a beam pumped oil well, the Series 1300 pump is powered by a direct connection to the movement of a walking beam, rod line, or rocker arm.

■ Single or dual-headed units available

■ Simple design, easy maintenance

| Head Size | Model | Pressure | Volume Range LPD |

|---|---|---|---|

3/16″ |

1304 |

3,000 |

0.24 to 2.08 |